QN QC4Industry

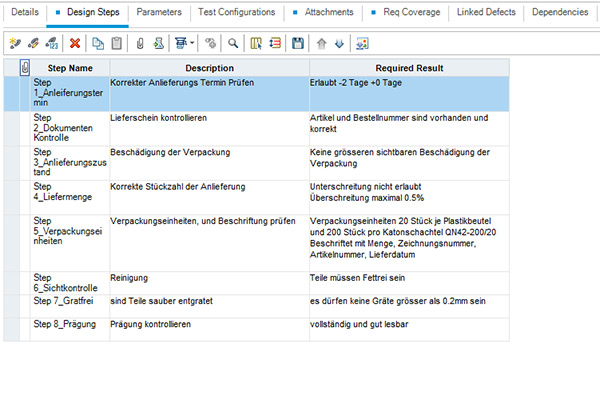

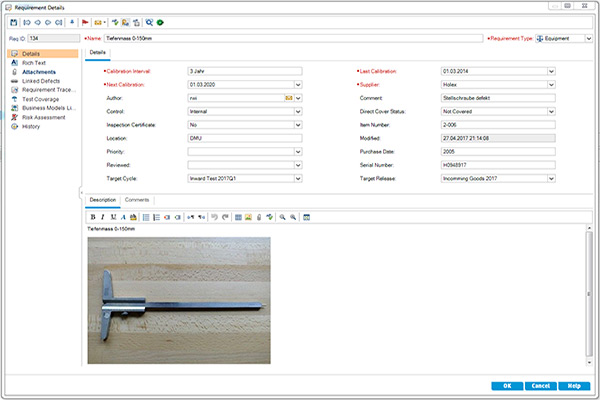

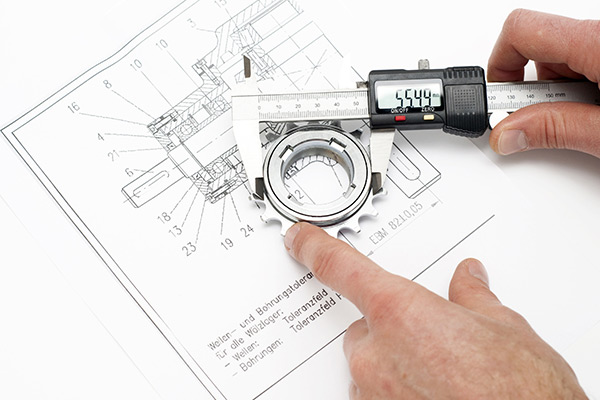

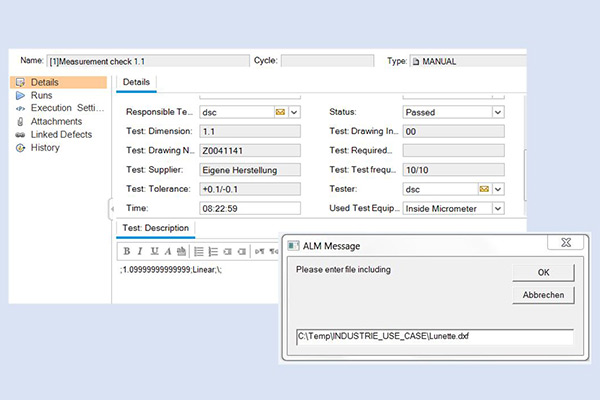

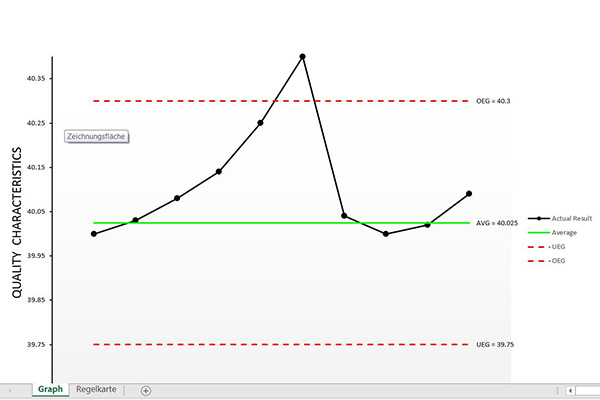

No matter the object or place of testing, whether single or serial parts, at the factory or customer: The Micro Focus Quality Center application (QC) provides a complete professional support for the entire quality assurance process. As user of QC, you will benefit from a fully digitalized quality assurance process preventing any time-consuming and cost intensive changes of media as well as real-time transparency at the push of a button.